Electrical boxes come in two main types: plastic and metal electrical Box. Choosing between them is often straightforward, especially when grounding is a concern.

In other cases, the decision depends on personal preference. Usually, DIY enthusiasts lean toward plastic boxes, while electricians work with both metal and plastic options.

When to Use Plastic vs. Metal Electrical Boxes

Here are common cases for choosing plastic or metal electrical boxes.

| Plastic Electrical Box | Metal Electrical Box |

|---|---|

| Used with plastic-sheathed (non-metallic) cable | Used with metallic-sheathed wire |

| Grounding done separately from the box | Grounding relies on the box itself |

| Box attached to drywall instead of studs | Attached to studs or in exposed areas |

| Installations with less strain on the box | When boxes need to be connected |

| Suitable when wall covering thickness is unknown (adjustable plastic boxes) | For heavy-duty setups needing strong boxes |

| Preferred by DIY beginners | Used by experienced DIY electricians |

Sometimes, there is overlap. For instance, plastic-sheathed cable always pairs with plastic boxes, but metal boxes can work with both plastic- and metallic-sheathed cables.

Grounding is an important factor. Metallic-sheathed cable grounds through its metal sheath, so it must touch a metal electrical box for proper grounding. Plastic-sheathed cable has a copper wire inside for grounding, separate from the box.

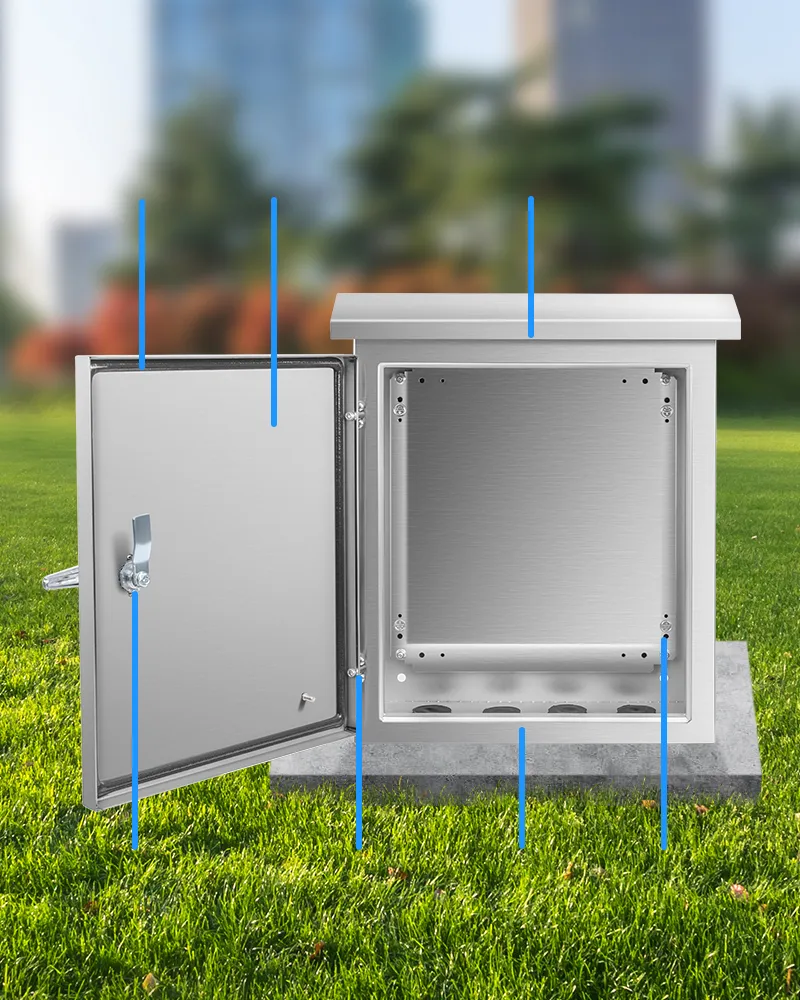

Metal Electrical Boxes

Cons

- Heavier than plastic boxes

- Knockouts can be hard to remove

- Sharp edges may cause injury

- Often require separate clamps for wiring

Pros

- Very strong and durable

- Resistant to melting

- Can be grounded easily

Metal electrical boxes have been in use long before plastic (PVC) boxes appeared. They are strong, fire-resistant, and do not melt, providing excellent protection for electrical wiring.

Compared to plastic boxes, metal ones are much tougher. They resist bending, warping, twisting, or crushing, making them very durable.

However, metal electrical boxes can be harder for DIYers to handle. They have knockouts on the sides and back that need extra clamps and can be difficult to remove. Also, the sharp edges may cause injury, so wearing gloves is recommended when working with metal boxes.

When Metal Boxes Are Required or Recommended

Metal electrical boxes should be used when metal-sheathed cable (also called armored BX cable) or metal conduit connects to the box. The metal sheath or conduit relies on contact with the metal electrical box to complete grounding.

Metal boxes are also ideal for locations where the box is exposed inside the building. Usually, boxes are installed inside walls, but in places like unfinished basements or mudrooms, walls might not be fully covered with drywall.

In these cases, the metal box is often mounted directly to a masonry wall. Since the wiring is exposed as well, metal conduit is necessary for protection and grounding.

Metal boxes can also be used with Romex or NM wiring, but extra care is needed to ensure proper grounding. Grounding is achieved either through contact between the device (like a switch or outlet) and the metal box or by attaching the bare or green grounding wire to the box with a screw.

Additionally, many metal electrical boxes can be connected together (ganged) to form larger assemblies, while most plastic boxes cannot. Some metal electrical boxes have removable side walls, allowing you to create double or triple gang boxes as needed.

Other Metal Box Considerations

Metal boxes are strong and offer a secure way to attach to studs. If a solid attachment to the stud is important, metal boxes are the best choice. They allow you to use strong screws for a firm hold.

Unlike plastic, metal boxes won’t warp. Their sturdy material often makes them stronger than the surrounding building materials. Some metal boxes come with built-in clamps to hold electrical cables, while others need separate clamps, which can increase the overall cost.

For DIY electricians, metal boxes can be a bit harder to handle than plastic ones. Wearing gloves helps make working with metal electrical boxes safer and more comfortable.

Plastic Electrical Boxes

Pros

- Built-in doors to secure cables

- Lightweight and easy to handle

- No sharp edges to cause injuries

- More affordable than metal boxes

Cons

- Can become twisted or misshapen

- Cables may be less firmly held

- Cannot provide grounding

- May melt if exposed to high heat

Plastic electrical boxes, made from polyvinyl chloride (PVC), are increasingly popular, especially among DIYers. They are lightweight, affordable, and easy to handle. The back and sides have knockouts that are simple to remove.

While PVC can melt if exposed to very high heat, it does not conduct electricity. Many plastic boxes include built-in clamps for securing wires, which helps reduce the total cost of a project.

When Plastic Boxes Are Required or Recommended

Using plastic electrical boxes with Romex (or NM) cables is recommended, though not mandatory. The electrical code does not require that NM cables be used only with plastic boxes.

The key issue is grounding. Metal-sheathed wiring relies on being bonded to a metal box for proper grounding. If metal-sheathed wires are placed in plastic boxes without additional grounding steps, the ground is broken, creating a serious safety risk.

Electrical boxes act as junction points where cables end or connect. They house outlets, light switches, ceiling lights, fans, and wire transitions.

Other Plastic Box Considerations

Plastic electrical boxes are simple for DIY home remodelers to use. The most affordable ones often come with nails pre-attached for easy mounting to studs. Marks on the box show the depth of 1/2-inch drywall to prevent the box face from sitting flush with the stud.

For remodels without stud access, old work or retrofit boxes have wings that attach directly to drywall.

Gangable plastic boxes exist but are rare. You need to know the box size beforehand, as plastic boxes can’t be taken apart and reassembled to create larger gang boxes.

Some plastic boxes include metal brackets that screw to studs and can be adjusted forward or backward with a screwdriver. These are the priciest but provide flexibility when wall thickness isn’t yet determined.

Many plastic boxes feature built-in clamp doors to hold cables without extra clamps.

On the downside, plastic boxes can become misshapen under stress and may crack from sharp impacts. The built-in door clamps, while handy, can make cable removal difficult. Also, old work boxes attached to drywall can loosen over time, and their wings often break.

FAQ

What is the difference between a junction box and a breaker box?

A junction box is where two or more electrical cables are safely connected or spliced. A breaker box, also called an electrical service panel, is a large metal box housing circuit breakers or fuses that control the home’s electrical circuits.

Do metal junction boxes always have to be grounded?

Yes, metal junction boxes must be grounded whether using NM (non-metallic) plastic-sheathed cable or metallic cable. Metallic cable is self-grounding if properly attached to the box. NM cable is not self-grounding and requires the bare copper wire inside the cable to be connected to a grounding screw inside the metal box.

Is it safe to put a plastic junction box in the attic?

Local electrical codes may permit placing junction boxes in attics, but it’s important to check with your local permitting office first. Metal boxes are stronger and more resistant to damage. If the attic is hard to access, it’s usually safer to install ceiling junction boxes facing downward so they can be opened from below.