In the photovoltaic system, solar panel wire connectors are needed in many links, such as the connection between solar panels, junction boxes and junction boxes.

The best way to connect solar panels

Solar panel wire connectors are the best way to connect solar panels. With the change of times, from the MC3 solar panel wire connector, which is not comprehensive yet, to the current MC4 solar panel wire connector.

The solar panel wire connector is a unique connection device between the solar panel array and the solar charging control device. Its function is to provide a safe and reliable connection between photovoltaic components and transmit the current generated by solar panels.

How to use solar panel wire connectors to connect solar panels and other photovoltaic components?

For the stability and reliability of the photovoltaic system, it is necessary to connect each component correctly. Below I will list the steps to use solar panel wire connectors to connect solar panels and other photovoltaic components:

1. First, you need to choose a suitable connector. The current industry standard connector for photovoltaic systems is the MC4 connector.

The MC4 connector is weatherproof and UV-resistant, providing a reliable and safe connection for the photovoltaic system.

When choosing an MC4 connector, you should also pay attention to the qualifications of the manufacturer. Need choose a reputable manufacturer.

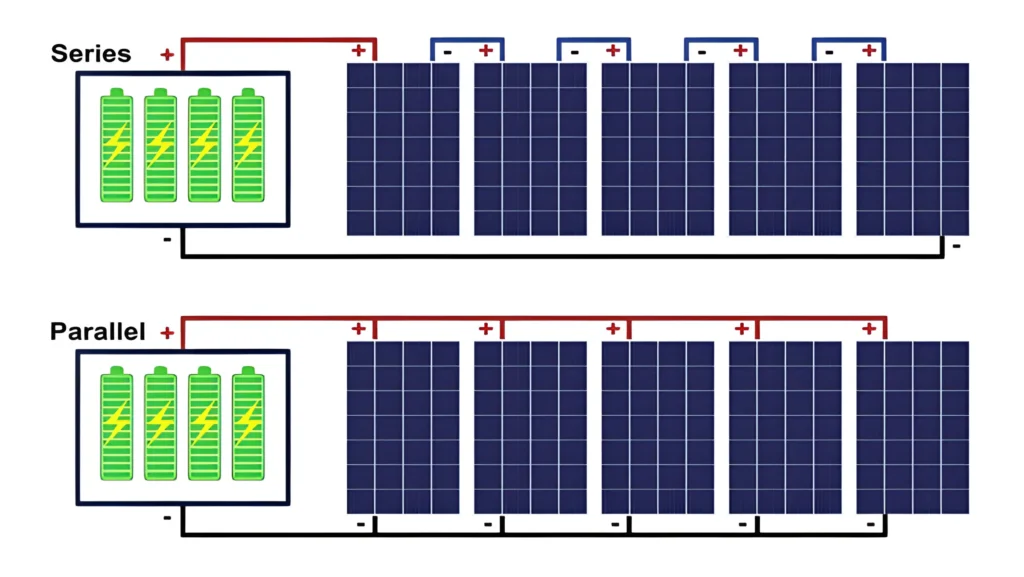

2. Then you need to determine the connection method, whether it is series or parallel. Series connection can increase voltage, while parallel connection can increase current, depending on the voltage and current requirements of the photovoltaic system.

Series connection: Connect the positive terminal of one solar panel to the negative terminal of another solar panel.

Parallel connection: Connect the positive terminal and negative terminal of two or more solar panels together.

3. Connect photovoltaic components such as solar arrays, charge controllers and inverters, and check the polarity carefully to avoid damage to each device during installation.

4. Test the connection to ensure that all connectors are properly connected and locked firmly.

Series connection and parallel connection

In the above text, solar panel connector have there are two connection methods in solar PV system, namely series connection and parallel connection. Now let me talk about the advantages and disadvantages of the two connection methods.

Advantages of series connection:

By connecting in series, the voltages of multiple solar panels will be added together to form a power supply with a higher output voltage, and there is no need to replace thicker output wires, which can save costs and is also helpful for applications that need to match specific equipment and applications that require long-distance power transmission.

In large solar panel arrays, the series connection method can reduce the length of the required cables and simplify the wiring design of the photovoltaic array, thus reducing the cost and complexity of installation. It also facilitates the maintenance of the subsequent solar panel array.

Disadvantages of series connection:

Solar panels connected in series need to have unified parameters and specifications to ensure overall efficiency. It is also not recommended to use series connection for solar panels of different brands, even if their electrical characteristics and other parameters are very similar.

In a series system, when any solar panel degrades due to various reasons, it will affect the efficiency of the entire photovoltaic system. This is the most important disadvantage, so if you use a series connection, it is recommended to purchase a complete set of photovoltaic systems and increase the frequency of system maintenance appropriately.

Advantages of parallel connection:

By connecting in parallel, the current of the entire photovoltaic system will increase. Since the voltage will not change, as many solar panels as possible can be connected without exceeding the inverter voltage limit. For example, if a 100W solar panel and a 200W solar panel are connected in parallel, the total output power is about 300W.

Solar panels in parallel will not interfere with each other, that is, if a solar panel degrades due to various reasons, other solar panels will not be affected. Compared with series connection, each solar panel in parallel connection is independent, and this can make the photovoltaic system more stable.

Disadvantages of parallel connection:

The cable wiring of parallel photovoltaic system is more complicated. Each solar panel needs to be connected with wires separately, which increases the complexity of the work, especially in photovoltaic systems with larger volumes.

Tools used in installing solar panel wire connectors

To install solar panel wire connectors on cables, you need to use tools such as cable strippers, terminal crimping pliers and cable glands. I will explain the specific functions of the tools in detail and attach pictures of the tools.

Cable strippers: The main function of cable strippers is to strip the insulation layer of the cable and show the metal part of the cable for subsequent crimping operations. It is one of the common tools for electricians.

Terminal crimping pliers: Terminal crimping pliers are used to connect cables to other electronic components. They can be used to connect different cables and terminals to ensure a firm electrical connection.

Terminal crimping pliers basically consist of two rotatable arms with several crimping holes of different sizes at the end of the arms. The wires to be connected are placed in the crimping holes and fixed by mechanical pressure.

This tool is made of carbide and has an ergonomic handle design. It is durable and is an essential tool for connecting wires in the power industry.

Cable gland: The function of the cable gland is mainly to fasten and seal the cable. The fastening design prevents the cable from shifting and rotating at will, and the sealing design prevents moisture and dust from easily entering the cable connection. The IP rating is usually used to objectively indicate the degree of sealing.