With the rapid development of photovoltaic (PV) power generation technology, photovoltaic combiner boxes have become a key component in PV systems. Their selection is crucial to the stable operation of these systems. This article will detail the functions and components of photovoltaic combiner boxes and guide you on how to choose the right combiner box to ensure the safety, reliability, and efficiency of photovoltaic systems.

Functions of Photovoltaic Combiner Boxes

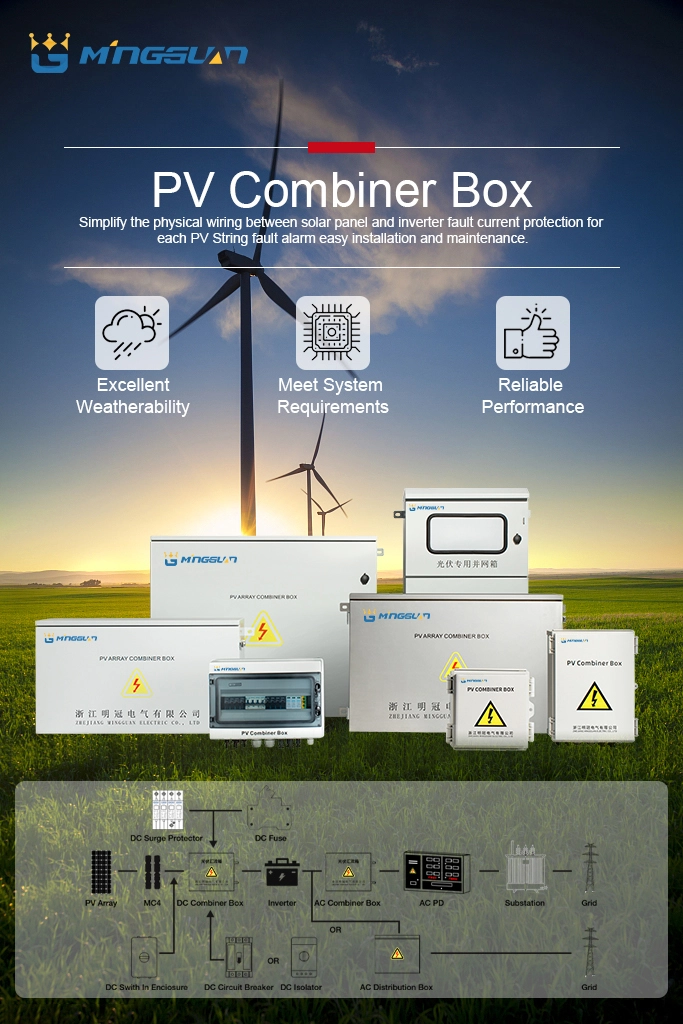

In solar panel systems, photovoltaic combiner boxes play a key role, especially in large installations. They mainly have the following functions:

1. Wiring Management: The combiner box acts as a centralized connection point for multiple panels, making electrical settings more orderly and safer. This simplifies the overall system architecture, reducing the complexity of wiring and making it easier to manage and troubleshoot the system.

2. Output Conduction: Depending on the system design, they direct the collective output of multiple panels into one connection, which is then connected to the inverter or charge controller. This consolidation of outputs ensures a more efficient and streamlined flow of electricity from the solar panels to the system’s main components.

3. Overcurrent Protection: Each combiner box has a built-in overcurrent protection device, which helps reduce unnecessary surges to the inverter, thereby extending the life of the inverter. This protection is crucial in preventing potential damage caused by unexpected increases in current flow.

4. Equipment Monitoring: Some combiner boxes are equipped with monitoring devices to alert you when problems occur. These devices require minimal maintenance, requiring only occasional inspections for leaks and loose connections. Monitoring capabilities can include real-time data logging and fault detection, which helps in maintaining optimal system performance.

Components of PV Combiner Boxes

A typical PV combiner box includes the following basic components:

1. DC Molded Case Circuit Breaker (MCCB): Protects the circuits in the solar system and is suitable for higher power PV systems. MCCBs are essential for isolating faults and preventing damage due to overcurrent or short circuits. They are available in various ratings to suit different system sizes.

2. PV String Fuse: Prevents overcurrent by interrupting the current during an incident, protecting cables and other equipment from further damage. Fuses are critical for ensuring that individual panel strings do not overload and cause system-wide issues.

3. DC Surge Protector (SPD): Protects the system from transient overvoltages, conducts surges to the ground, and protects downstream equipment. SPDs are important for safeguarding the system against lightning strikes and other surge events.

4. Miniature Circuit Breaker: Disconnects or isolates the circuit during a surge or short circuit. These breakers provide an additional layer of protection and can be reset after a fault has been cleared.

5. Busbar: A conductive metal strip with multiple connection points that is used to connect the negative or ground lead of a solar panel. Busbars facilitate the consolidation of multiple connections into a single point, improving the efficiency of the electrical layout.

6. PV Connector: Provides safe and reliable electrical connections between PV panels and other system components such as inverters, charge controllers, and batteries. PV connectors are designed to be durable and weather-resistant, ensuring long-term performance in outdoor environments.

7. Housing: The physical box that houses the combiner components, usually made of PV or ABS materials, with an IP65 rating for dust, water, and UV protection. The housing ensures that the internal components are protected from environmental factors and physical damage.

PV Combiner Box Selection Guide

Choosing the right PV combiner box is essential to ensure the stable operation of the PV system. The following are key factors to consider:

1. Electrical Parameters

1. Rated Voltage: The rated voltage of the combiner box should match the output voltage range of the PV module. Common rated voltages include DC 1000V and 1500V. Ensuring compatibility with the system’s voltage requirements is critical to prevent electrical faults and ensure efficient operation.

2. Rated Current: Make sure the rated current of the combiner box can handle the output current of the PV module to prevent damage to the equipment due to excessive current. The current rating should be carefully chosen based on the expected load and potential peak currents.

3. Input Circuits: Select the appropriate number of input circuits according to your system design. Common options include 8-way and 16-way. The number of input circuits will depend on the number of PV strings and the overall system configuration.

2. Quality and Certification

1. Certification Standards: Choose a combiner box that meets international and domestic certification standards such as TUV, CE, UL, etc., to ensure high reliability and safety. Certifications indicate that the product has been tested and meets stringent safety and performance criteria.

2. Brand and Reputation: Choose a brand with a good market reputation and strong after-sales service. Please refer to user reviews and experiences for guidance. Established brands often offer better warranties and customer support, which can be crucial for long-term system reliability.

3. Protection Functions

1. Lightning Protection: Choose a combiner box with lightning protection function to prevent damage caused by lightning strikes. Lightning protection is especially important in regions prone to thunderstorms.

2. Overcurrent Protection: Choose a combiner box with overcurrent protection, which can automatically cut off the circuit when the current is too large. This prevents potential damage to the system components and ensures safe operation.

3. Short Circuit Protection: Make sure the combiner box has a short circuit protection function, quickly disconnecting the circuit in the event of a short circuit to prevent fire and equipment damage. Short circuit protection helps in maintaining system integrity and safety.

4. Environmental Adaptability

1. Protection Level: Choose a protection level suitable for the installation environment, usually IP65 or higher, to ensure dust and water resistance. High protection levels are necessary for outdoor installations where the combiner box is exposed to the elements.

2. Temperature Adaptability: Choose a combiner box that can operate over a wide temperature range to ensure stable performance under extreme temperatures. Temperature resilience ensures that the system can function reliably in both hot and cold climates.

5. Installation and Maintenance

1. Ease of Installation: Choose a combiner box that is easy to install to reduce installation time and labor costs. User-friendly designs with clear instructions can significantly streamline the installation process.

2. Ease of Maintenance: Choose a combiner box with a reasonable structure to facilitate quick repair and maintenance and minimize downtime. Accessible components and modular designs can make maintenance more straightforward and efficient.

6. Price and Cost

1. Cost-Effectiveness: Consider price and overall quality and features. Compare different brands and models to find one that meets your needs and is cost-effective. While it is important to manage costs, investing in a high-quality combiner box can save money in the long run by reducing maintenance needs and preventing system failures.

Conclusion

Choosing the right PV combiner box is essential to ensure the safe, stable, and efficient operation of your PV system. By considering electrical parameters, quality and certification, protection characteristics, environmental adaptability, installation and maintenance, and cost, you can choose the right combiner box to ensure the long-term and reliable operation of your PV system. We hope this guide provides valuable insights to help you make an informed decision when choosing a PV combiner box.